Geobera

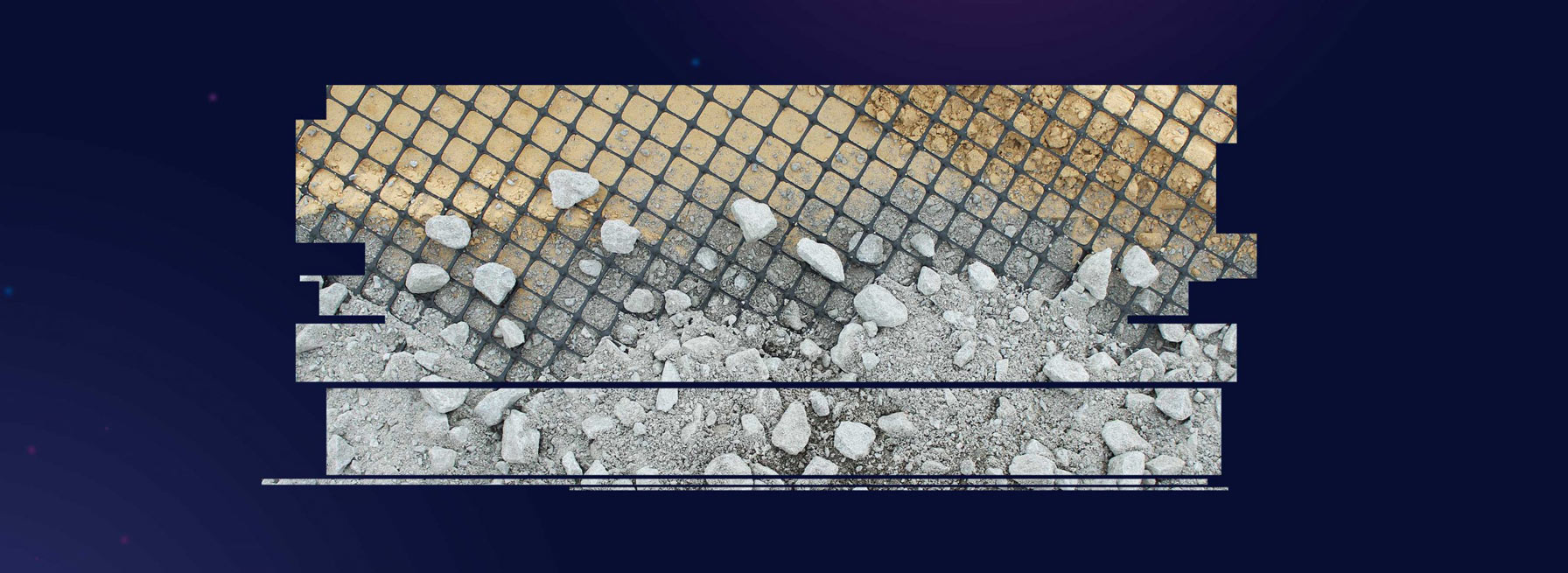

Geosynthetics are produced in factory conditions. In solving the geotechnical problems encountered in transportation projects, it provides many advantages such as space saving, material quality control, manufacturing quality control, cost savings, technical superiority, shortening of construction time, material development, material availability and environmental sensitivity.