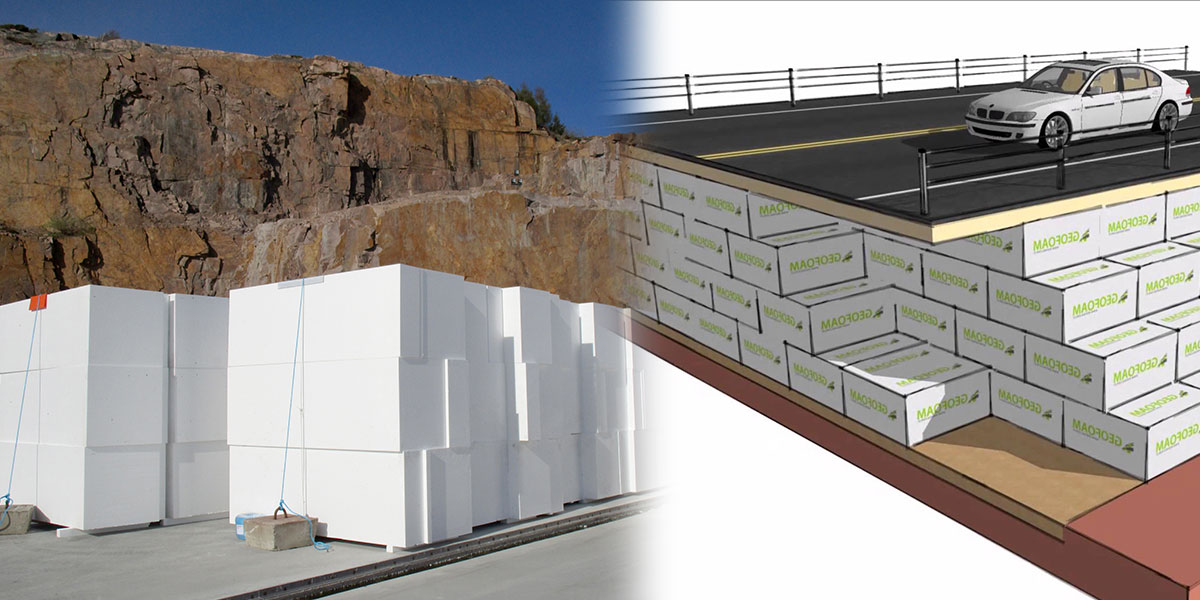

The insulation material geofoam (expanded polystyrene) is not only used in building construction. The ecological insulation material is used in classic civil engineering, especially in road construction. The material then called geofoam blocks has a completely different advantage than its otherwise good thermal insulation properties. Due to its low density and closed surface, it serves as a filler material and has the advantage that it does not sink like gravel, for example. This increases the stability of the road and there is significantly less damage from settlement behavior. Especially on bridges, the insulation material is built under the driveways in order to keep the difference in height between the driveway and bridge as low as possible over the years. Large geofoam blocks for sale are used that are clipped together. Due to the size, the installation is much easier, faster and cheaper. The eps geofoam blocks arealso cheaper to buy than the otherwise used fillers.

Large Geofoam Blocks for Quick Processing

The size comparison shows the geofoam block sizes in comparison to conventional insulation boards. Higher pressure resistance classes are used so that the geofoam can withstand the traffic load. The sizes are adapted to optimized handling on the construction site so that the material can be processed quickly and efficiently. The geofoam blocks can be individually adapted to the requirements. As Geobera which has been exporting many different products to the USA, Kosovo, Bulgaria, Georgia, Malta, Greece, France, Italy with our other products, there are also standard dimensions:

- 5,000 x 1,250 x 1,000 mm

- 5,000 x 1,250 x 500 mm

- 2,500 x 1,250 x 1,000 mm

- 2,500 x 1,250 x 500 mm

Other formats are available on request.

Construction Geofoam: Work Properly with Assembly Foam

Sealing, filling, fixing or insulating: construction foam in geofoam applications , also known as assembly foam or PU foam, can be used in many ways and effectively in construction at least if you know how to use it properly. Here we make the differences between 1- and 2-component construction foam clear to you and show you common application errors. Whether for inserting into gaps in the masonry, for sealing joints or for other cavities and spaces: the hero in the game is called construction foam. Many craftsmen rightly appreciate it. But caution is advised: Because only if you know how to use PU foam in a targeted manner can it develop its full effect.

Assembly Geofoam: What Exactly Is It?

First of all, a brief general classification: This geofoam for sale from the bottle is a substance that is initially liquid, then swells and solidifies and so fits easily into any desired crack. As soon as the PU foam, short for polyurethane foam, has hardened in the desired place, it promises absolute hold; be it on doors, windows or to close cracks. Construction foam is therefore also ideal for insulating and gluing on construction. In the Geobera shop you will find a first-class selection of construction foam. They all work in slightly different ways: while in the professional sector rapid curing and curing of the foams is particularly important so that other trades can continue to work, in the private sector, for example, ecological factors are more important. In addition to PU-based assembly geofoam specification, there are also variants based on acyl. However, acrylates have the disadvantage that they are not frost-resistant. So here you should think carefully about which active principle is more suitable for your purpose.

- One-Component Construction Geofoam: The Simple Solution

If you want to fall back on the classic, which also works quite simply, then you are spot on with PU foam in the form of 1-component foam. A hardener is not included here. The solidification works practically by itself or “naturally” due to the humidity of the environment. Vigorous shaking of the foam container usually with aerosols ensures that the humidity and the pure, ready-to-use construction foam react with one another.

- Two-Component Geofoam: Including Hardener

The aerosol variant is characterized by two components that are already available directly in the pressure bottle. In this case you have to activate the integrated hardener yourself. Only then do the ingredients mix as desired. The manufacturers have come up with a few things to make it work. Everyone does it a little differently.

- Double Cartridge Geofoam: Reaction in The Mixing Tube

So-called double cartridge foam reacts differently again. What makes it unique? Well, the two contained components only come together during application in the mixing tube. This foam really hardens extremely quickly. So you don't have to wait and constantly check when it has become firm enough. Before buying, it is best to pay attention to the following technical standards and notes in the manufacturer's information:

Technical Specifications for Geofoam Selection |

| 1- Fine-cell foam structure without air bubbles |

| 2- High dimensional stability |

| 3- Broad range of liability |

| 4- RAL and EnEv conformity |

| 5- CE marking |

| 6- EN 15851 |

If you want to get more information about geofoam blocks installation, geofoam and geofoam block price, as well as eps geofoam price etc. you can check our other articles on website out. We would be very pleased to help you out with our free-charge consultation service.