Geosynthetic products are synthetic materials used in civil engineering that have several properties making them useful in various applications. They are strong and can withstand forces like tension, compression, and puncture. Additionally, geosynthetics can be made to be permeable or impermeable, resist degradation from UV exposure, chemicals, and biological factors, and be flexible or stiff to adapt to different shapes and contours.

What is Geosynthetics?

Geosynthetics are synthetic materials made from polymers that are used in civil engineering applications for various geotechnical and environmental purposes. They are used in the construction, repair, and maintenance of civil engineering structures, such as roads, embankments, retaining walls, drainage systems, landfill liners, and geotextiles.

Geosynthetics are designed to perform specific functions, such as separation, reinforcement, filtration, drainage, and erosion control. They are typically manufactured from polymers such as polypropylene, polyester, or polyethylene, and can be produced in a variety of forms including geotextiles, geogrids, geocells, geomembranes, and geocomposites.

Geosynthetics have many advantages over traditional construction materials, including their lightweight, high strength, durability, and resistance to environmental factors such as chemicals, UV light, and weathering. They are also easy to install and can save time and costs compared to traditional construction methods. As a result, geosynthetics have become an essential component of modern civil engineering and construction practices.

What Are the Types of Geosynthetics?

There are several types of geosynthetics, each with its own unique characteristics and functions. Some of the most common types of products used for geosynthetic engineering include:

- Geotextiles: Geotextile is a geosynthetic fabric used for filtration, drainage, and separation in civil engineering applications.

- Geogrids: A high-strength mesh material used for soil stabilization, reinforcement, and slope protection.

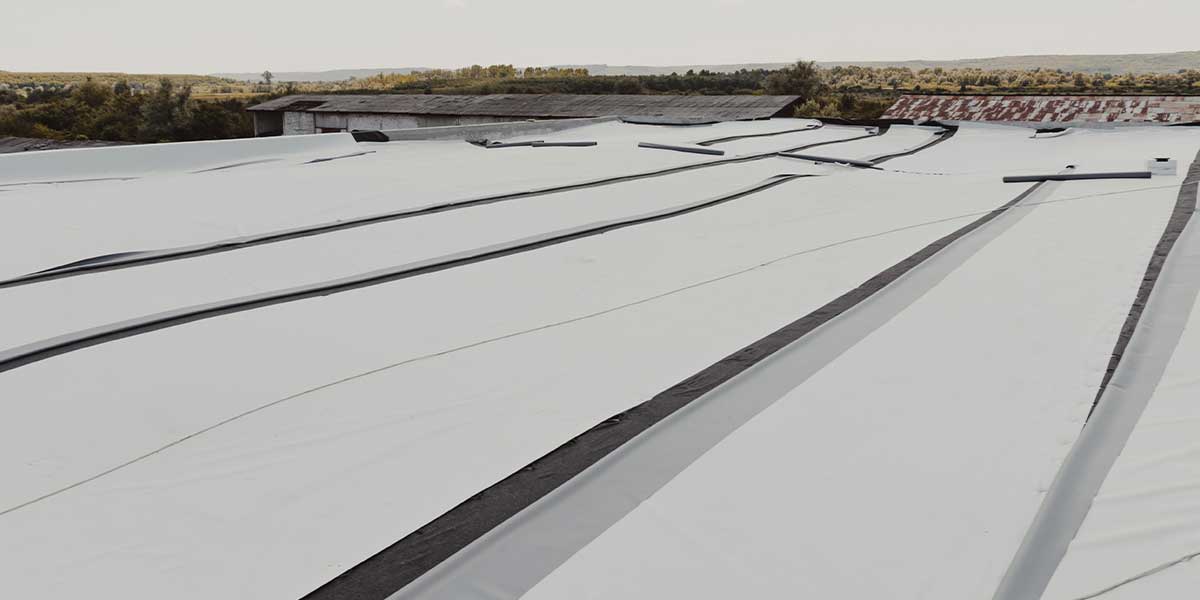

- Geomembranes: A waterproof sheet used for containment and barrier applications, such as landfill liners or pond liners.

- Geocells: A three-dimensional honeycomb-like structure made from geotextiles or plastic sheets, used for erosion control, soil stabilization, and load support.

- Geonets: A combination of geotextiles and geogrids, used for drainage and filtration applications.

- Geocomposites: A combination of two or more geosynthetic materials, used for various applications such as soil reinforcement, drainage, and erosion control.

Each type of geosynthetic has specific properties and functions that make it suitable for different applications in civil engineering and environmental protection. The choice of geosynthetic depends on the specific needs and requirements of the project.

Where to Use Geosynthetics?

Geosynthetics are versatile materials that can be used in various civil engineering and environmental protection applications. They are commonly used in geotechnical engineering projects such as soil stabilization, slope reinforcement, retaining walls, and foundation systems.

Geosynthetics are also effective in environmental protection applications such as erosion control and landfill liners. They can also be used in transportation projects such as roads and railroads for separation, drainage, and reinforcement purposes. Additionally, geosynthetics are used in hydraulic engineering applications such as dams, canals, and reservoirs for drainage and filtration purposes.

What Advantages Does Geosynthetics Offer?

Geosynthetics offer several advantages over traditional construction materials in civil engineering and environmental protection applications. Some of the key advantages of geosynthetics include:

- Cost-effective: Geosynthetics are generally more cost effective than traditional materials due to their lightweight and easy installation, which can save time and reduce labor costs.

- Durable: Geosynthetics are highly resistant to environmental factors, such as UV light, chemicals, and weathering, making them more durable and longer-lasting than traditional materials.

- Versatile: Geosynthetics can be designed and produced in a wide range of shapes, sizes, and properties to meet specific project requirements, making them highly versatile.

- Easy to install: Geosynthetics are lightweight and easy to install, which can significantly reduce installation time and costs.

- Increased safety: Geosynthetics can be used to improve safety in civil engineering structures by providing reinforcement and stability, reducing the risk of failure and collapse.

Overall, geosynthetics offer a range of advantages that make them a preferred choice in many civil engineering and environmental protection applications.

What Is the Cost of Geosynthetics?

The cost of geosynthetics can vary depending on several factors, such as the type of geosynthetic, the application, the required properties, and the amount needed for the project. Generally, geosynthetics are more cost effective than traditional construction materials due to their lightweight and easy installation, which can save time and reduce labor costs. However, some geosynthetics, such as geomembranes, can be more expensive than other types due to their high strength and waterproofing properties.

It is difficult to provide a specific cost for geosynthetic clay liners without knowing the specific project requirements. However, it is recommended to obtain quotes from multiple suppliers and compare costs and benefits to determine the most suitable option for the project. In general, the cost of geosynthetics should be considered alongside the potential long-term savings in terms of reduced maintenance, increased durability, and improved safety.